-

Product Catalog

- Security and Surveillance Systems

- Automatic Circuit Breakers for Direct Current (DC) Circuits with Integrated Overload, Short-Circuit, and Voltage Stabilization Protection Functions

- Lighting with the help of electrical energy

-

Automation and Control Systems

- Automation control accessories

- Control components for automation and control systems

- Passive lifting | unloading | transporting magnets

- Signal converters | controllers for automation control | for control systems

- Touchscreens | panels for automation control | control systems

- Power Contactors | Control Circuit Intermediate Relays

- Optical sensors | detectors for automation devices

- Automation control | Data transmission | Low current

- Sealing profiles | rubber | gaskets | strips Inflatable Liquid Storage Tanks | Reservoirs | Bladders Inflatable rubber plugs for sealing high-pressure plumbing pipes

-

Electrical distribution and installation

- Electrical power | power cables | wires with copper conductors

- Electrical Energy Supply | Distribution Panels | Boxes | Accessories

- Smart Automated Products | Control | Transmission | Detection

- Modular equipment installed in electrical distribution boxes | panels

- Smart electrical network analyzers

- Reliable power management | stabilization | control | uninterrupted supply

- Fuse holder blocks

- Fuse disconnectors

- Fuses

- Electrical installation components

- For domestic | professional use Extension cords | power supply extensions

- Industrial | domestic socket outlets | plugs | adapters for electricity supply

- Solar Energy Generation and Management Equipment

-

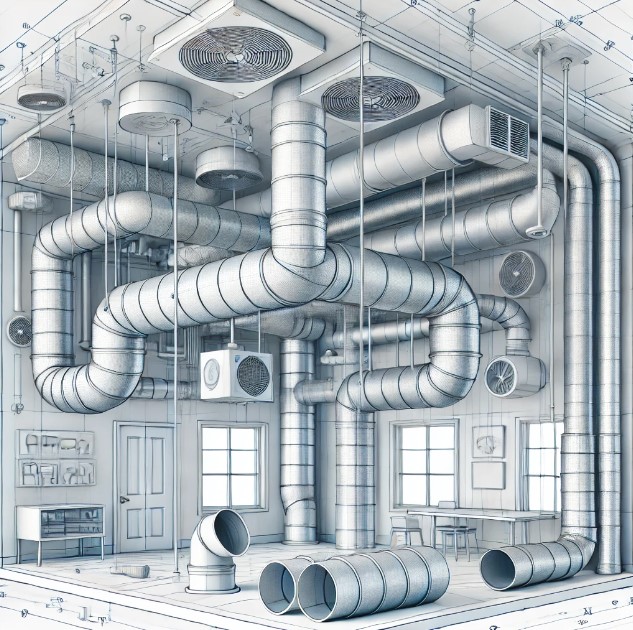

HVAC control solutions for heating and ventilation.

- HVAC automation

- Fans for ventilation systems

- Ducts and connections for ventilation | air conditioning systems

- Chimney Caps | Deflectors | for Ventilation and Chimney Systems

- Dampers for ducts | ventilation | air conditioning systems

- Duct Silencers | Ventilation | Ventilation Systems

- Air Filters for Ducts | Ventilation | Ventilation Systems

- Supply Air Ventilation Dampers

- Diffusers for Ventilation Systems

- Mobile Air Conditioners | for Indoor Climate Control

- Domestic | industrial air purification systems

- Special products and accessories

- Other products

- Safety tools

- Quality used products

- ABOUT US

Products catalog

-

Product Catalog

-

Security and Surveillance Systems

- IP Surveillance Security Cameras

- Network Accessories | Network Cables | RJ45 Connectors | PoE Injectors | Wi-Fi Extenders (Repeaters) | Wi-Fi Routers

- Video and Audio Recording Devices and Accessories

- Low Voltage | Power Supply Accessories

- Intercoms

- Automatic Circuit Breakers for Direct Current (DC) Circuits with Integrated Overload, Short-Circuit, and Voltage Stabilization Protection Functions

-

Lighting with the help of electrical energy

-

Commercial lighting

- Industrial lights for high-ceiling spaces

- Emergency lighting

- Lights for corridors | staircases | basement

- LED floodlights | street | park lights

- Optical Fiber

- Moisture-resistant hermetic luminaires | enclosures

-

Industrial LED lamps | HQL analogs | NAV lamps

- Industrial LED lamps | alternatives to mercury vapor lamps (HQL) E27 base

- Industrial LED lamps | analogs for mercury vapor lamps (HQL) E40 base

- Industrial LED bulbs | alternatives to sodium vapor lamps (NAV) E27 base

- Industrial LED bulbs | Alternatives to sodium vapor lamps (NAV) E40 base

- Industrial UFO type LED lamps | analogs for high-intensity discharge (HID) lamps E40 socket

- Office lighting

- Indoor Interior Lighting

- Outdoor lights

- Lamps | bulbs

- Control of Flexible LED Strips

- Motion | presence sensors | detectors

- LED modules

- LED flexible strips hermetic | non-hermetic | accessories

- Accessories for light fixtures | adapters | sockets | holders

-

Commercial lighting

-

Automation and Control Systems

-

Automation control accessories

- Time voltage deviation current level network control visualization relay

- Signal tower modules | accessories

- Power and time control relays for home automation with integrated SCHUKO sockets, designed for alternating and direct current protection and for household users.

- Boxes for signaling equipment | Signal lights

- Cam switches | for devices on/off control

- Electric motor control | protection management

- Soft starter devices for electric motors

- Energy meters

-

Control components for automation and control systems

-

Sensors | Detectors for automation | Control | Management systems

- End-position mechanical switches for automation control | control systems

- End-position micro switches for automation control | control systems

- Non-contact inductive sensors for detecting metallic objects in automation control | monitoring systems

- Non-contact ultrasonic sensors for object detection in automation control | monitoring systems

- Inductive Sensor Accessories for Automation Control | Monitoring Systems

- Non-contact photoelectric sensors for automation control | monitoring systems

- Trolleys | Crane Control Panels | Hoist Control | Joystick

- Foot control pedals for industrial equipment management

- Audible signals 22/28mm for automation control | control systems

- Additional accessories | components for buttons in automation control | control systems

- Buttons for automation control | control systems

- Switches | Keys for automation devices control | control systems

-

Sensors | Detectors for automation | Control | Management systems

- Passive lifting | unloading | transporting magnets

- Signal converters | controllers for automation control | for control systems

- Touchscreens | panels for automation control | control systems

-

Power Contactors | Control Circuit Intermediate Relays

- Mini contactors for electric motor control

- Contactors | Electrical starters | For equipment control

- Electromechanical thermal relays | electrical equipment protection

- Contactors with enclosure and control buttons | for electrical equipment control

- Control coils for contactors | starters | electrical equipment control

- Adapters-converters for relays and contactors

- Additional contacts | Accessories for contactors

- Relays for electrical equipment automation control | monitoring

- Relay sockets | for connecting relays to the control system

- Relay modules | for the safe operation of electrical equipment

- Optical sensors | detectors for automation devices

- Automation control | Data transmission | Low current

-

Automation control accessories

- Sealing profiles | rubber | gaskets | strips

- Inflatable Liquid Storage Tanks | Reservoirs | Bladders

- Inflatable rubber plugs for sealing high-pressure plumbing pipes

-

Electrical distribution and installation

-

Electrical power | power cables | wires with copper conductors

- Copper power supply cables KH05VV-U (NYM-J)

- Copper power supply cables BVV-LL

- Copper power supply cables CYKY-L

- Copper power supply cables H03VVF, H05VV-F

- Copper power supply cables BVV-PLL

- Copper power supply wires H05V2-K, H07V2-K

- Copper power supply cables BVV-P

- Copper power supply cables BVV-F, BVV-PL

- Copper power supply wires H05V-K

- Copper power supply wires H07V-R, H07V2-R

- Copper power supply wires H07V-K

- Copper power supply wires H05V-U, H07V-U, H05V2-U, H07V2-U

- Halogen-free copper power supply cables H07Z1-K

- Copper power supply cables halogen-free BZ1Z1-P

- Copper power supply cables halogen-free NHXMH-J

- Aluminum power supply cables

- Computer power supply cables

- Self-regulating | heating power supply cables

- Special purpose power supply cables

- Copper | vintage | retro style braided cables

-

Accessories for power supply cables

- Wire trays | channels for power supply cables | wires

- Cable trays | channels for power supply cables | wires

- Lighting cable trays | channels for power supply cables | cable management

- Cable ladders for power supply cables | wires

- Accessories for metal power supply cable | wire channels | trays

- Cable laying | fixing | installation structures

- Installation cable trays | channels for electrical cables | wires | plastic

- Electrical cable | wire identification markers | marking tools

- Surface-mounted hermetic instalation boxes for electrical cables | wires

- Connectors and sleeves for cables

- Thermally shrinking insulating gloves | hermetically seal electrical wires | cables

- Heat shrink tubing | insulating electrical wires | cables

- Electrical insulating tapes | for electrical wires | cables

- Spiral strips | for concealing electrical wires | cables

- Gels | lubricants for wire | cable pulling

- Insulating gels for protecting electrical wires | cable connections | contacts from humidity

- Warning hazard | caution marking tapes

- Dielectric insulating sheaths for the protection of electrical cables | wires

-

Electrical Energy Supply | Distribution Panels | Boxes | Accessories

- Single-phase | three-phase electricity metering boxes

- Electrical energy distribution | metering boxes for apartments

- Surface-mounted electrical power panels | boxes

- Flush-mounted electrical distribution panels | boxes

- Special electrical panels for garages | panels designed for commercial premises

- Portable electrical distribution | panels | enclosures | boxes

- Electric current transformers

- Switch disconnector for electrical cabinets | accessories

- Sealing products | seals for electrical wires | cables | panels | boxes

-

Terminals | connections for electrical cables | distribution | connection

- Power distribution terminals for electrical wires | cables

- WAGO terminal blocks for electrical wire | cable connections

- Connectors for electrical wires | cable connections

- Installation terminals for connecting electrical wires | cables of fixtures

- Grounding terminals for connecting electrical wires | cables

- Branching terminals for electrical wires | cable connections

- Rear covers for spring assemblies

- Busbar grounding and protection systems

- Soldering components | connection solutions

- Screen terminals for connecting electrical cables | wires

- Accessories for terminals | electrical contacts

- Spring terminal blocks | electrical connections | on DIN rail

- Spring lever terminal blocks for electrical wire | cable connections

- Terminals for connecting electrical wires | cables | mounted on a DIN rail

- DIN rails for mounting modular equipment in the electrical distribution panel

- Accessories for electrical distribution panels | boxes

-

Smart Automated Products | Control | Transmission | Detection

- Smart Emergency Call System SOS

- Smart Office Management Solutions

- NOUS smart | automated control

- WOOX Smart | Automated Control

-

SONOFF Smart | Automated Control

- Sonoff Smart Switches | Touch Switches

- SONOFF temperature | humidity sensors | controllers

- SONOFF smart home control panels

- SONOFF smart switches

- SONOFF smart motion sensors

- SONOFF smart energy meters

- SONOFF smart Schuko sockets

- SONOFF other products | accessories

- SONOFF smart home hubs

- SONOFF smart lighting control

- SONOFF smart flexible LED strips

- SONOFF Smart Surveillance | Security Cameras

- iNELS RF smart | automated control

- TUYA Smart | Automated Control

-

Modular equipment installed in electrical distribution boxes | panels

-

Circuit breakers | installed in electrical distribution boxes | panels

- Schneider Electric circuit breakers | installed in electrical distribution boxes | panels

- Industrial circuit breakers

- Promfactor Baltic circuit breakers | installed in electrical distribution boxes | panels

- Noark circuit breakers | installed in electrical distribution boxes | panels

- SIEMENS automatic circuit breakers | installed in electrical boxes

- Hager automatic circuit breakers | installed in electrical distribution boxes | panels

- Legrand automatic circuit breakers | installed in electrical distribution boxes | panels

- IEK automatic circuit breakers | installed in electrical distribution boxes | panels

- Merlin Gerin automatic circuit breakers | installed in electrical distribution boxes | panels

- Eaton automatic circuit breakers | installed in electrical distribution boxes | panels

- Accessories for circuit breakers

- Power contactors | installed in electrical distribution boxes | panels

-

Modular leakage relays | installed in electrical distribution boxes | panels

- Promfactor Baltic leakage relays | mounted in electrical distribution boxes | panels

- Legrand leakage relays | mounted in electrical distribution boxes | panels

- Schneider Electric leakage relays | installed in electrical distribution boxes | panels

- Eaton leakage relays | mounted in electrical distribution boxes | panels

- Voltage relays modular | mounted in electrical distribution boxes | panels

- Current relays modular | installed in electrical distribution boxes | panels

- Power limiters modular | installed in electrical distribution boxes | panels

- Phase switch modular | mounted in electrical distribution boxes | panels

- Temperature controllers | modular thermostats | designed for mounting in electrical distribution boxes | panels

- Modular time relays | installed in electrical distribution boxes | panels

- Digital ammeters | voltmeters modular | mounted in electrical distribution boxes | panels

- Photo relays | twilight switches | mounted in electrical distribution boxes | panels

- Other modular relays | mounted in electrical distribution boxes | panels

-

Circuit breakers | installed in electrical distribution boxes | panels

- Smart electrical network analyzers

- Reliable power management | stabilization | control | uninterrupted supply

- Fuse holder blocks

- Fuse disconnectors

- Fuses

-

Electrical installation components

- Socket outlets for furniture installation

- Sedna Recessed Electrical Installation by Schneider Electric

- Hermetic surface-mounted electrical installation IP44 | IP54 | IP66

- Surface-mounted electrical installation

- Hermetic flush-mounted electrical installation IP55

- Recessed electrical installation

- Installation electrical boxes for drywall | masonry

- Distribution mounting boxes are designed to be installed in drywall | masonry

- Boxes mounted in the floor | for socket installation

- Vintage | Retro Style Electrical Installation Components

- Electrical installation "Vilma"

- For domestic | professional use Extension cords | power supply extensions

-

Industrial | domestic socket outlets | plugs | adapters for electricity supply

- Household single-phase plugs | industrial single-phase | three-phase for electricity supply

- Plug sockets for household single-phase | industrial single-phase | three-phase electrical power supply

- Adapters (transitions) for household | industrial power supply

- Sockets mounted on a DIN rail | for power supply

- High Voltage Equipment | Components 6kV | 10kV | 12kV | 20kV

-

Underground Power Transmission | Overhead Power Lines

- 0.4kV Overhead Line Metal Structures for Uninsulated Wires

- 10kV Overhead Line Metal Structures with Non-Insulated Conductors

- Metal structures for 0.4kV overhead lines with insulated wires

- Clamps for air line cables | cables | equipment mounting

- Cable supports for overhead lines

- Air line terminals

- Air line crossbars for SZ circuit breakers

- Airline covers | Wire frames | Cable mounting

- Airline metal structures | traverses | tops

- Insulators for Electrical Power Airline Lines

- Overhead power cables | wires for electricity supply

- Surge Protection and Lightning Protection

-

Electrical power | power cables | wires with copper conductors

- Solar Energy Generation and Management Equipment

-

HVAC control solutions for heating and ventilation.

- HVAC automation

- Fans for ventilation systems

-

Ducts and connections for ventilation | air conditioning systems

-

Ducts for ventilation | ventilation systems

- Sealing tapes for duct systems

- Rigid ducts for ventilation | air conditioning systems | plastic

- Flexible ducts for ventilation systems | aluminum

- Flexible ducts for ventilation | vent systems | stainless steel

- Flexible ducts for ventilation systems | metal

- Flexible ducts for ventilation | ventilation systems | PVC film

- Rigid ducts for ventilation | air conditioning systems | galvanized steel

- Square | rectangular | rigid ducts | for ventilation systems | plastic

-

Square | rectangular ducts | ventilation | ventilation systems | plasticSquare | rectangular ducts | ventilation | ventilation systems | plastic

- Holders for square ducts | ventilation systems | plastic

- Connections for square ducts | ventilation | ventilation systems | elbows 3°-49° | plastic

- Connectors for square ducts | ventilation | ventilation systems | 90° elbows | plastic

- Connections for square ducts | ventilation | ventilation systems | fittings | plastic

- Connections for square ducts | ventilation | ventilation systems | T-shaped | branch fittings | plastic

- Connections for square ducts | ventilation systems | sleeves with a backdraft damper | plastic

- Wall connectors for square ducts | ventilation systems | adapters | plastic

- Ducts | Ventilation | Ventilation Systems | Metal

-

Ducts | ventilation | ventilation systems | plastic

- Connections for ducts | Ventilation systems | 45° elbows | Plastic

- Duct connections | ventilation systems | 90° elbows | plastic

- Connections for ducts | Ventilation systems | Couplings | Plastic

- Connectors for ducts | ventilation systems | transitions | adapters | plastic

- Connectors for ducts | ventilation systems | T-shaped | three-way | plastic

- Duct connections | ventilation systems | flanges | plastic

- Duct connections | ventilation systems | condensate collector | plastic.

- Connections for ducts | ventilation systems | flexible connectors with backflow valve | plastic

- Wall connectors for ducts | ventilation systems | adapters | plastic

- Holders for ducts | ventilation systems | plastic

-

Ducts | ventilation | ventilation systems | galvanized steel

- Duct fittings | ventilation systems | 45° elbows | galvanized steel

- Connections for ducts | Ventilation systems | 90° elbows | Galvanized steel

- Duct ventilation hoods | chimneys | for ventilation systems | galvanized steel

- Connectors for ducts | ventilation systems | T-shaped | tees | galvanized steel

- Connectors for ducts | ventilation systems | transitions | adapters | galvanized steel

- Connections for ducts | ventilation systems | sleeves | galvanized steel

- Flexible connectors for ducts | ventilation systems | sleeves | galvanized steel

- Connectors for ducts | ventilation systems | connectors with back-draught shutter | galvanized steel

- Holders for ducts | ventilation systems | galvanized steel

- Connectors for ducts | ventilation systems | branches | galvanized steel

- End caps for ducts | ventilation systems | galvanized steel

- Transitions | adapters for square and round ducts | ventilation | ventilation systems | plastic

-

Ducts for ventilation | ventilation systems

-

Chimney Caps | Deflectors | for Ventilation and Chimney Systems

- Galvanized Steel Chimney Hoods | Deflectors | for Ventilation and Chimney Systems

- Painted Steel Chimney Hoods | Deflectors | for Ventilation and Chimney Systems

- Stainless Steel Chimney Hoods | Deflectors | For Ventilation and Chimney Systems

- Plastic chimney caps | deflectors | for ventilation and flue systems

- Dampers for ducts | ventilation | air conditioning systems

- Duct Silencers | Ventilation | Ventilation Systems

- Air Filters for Ducts | Ventilation | Ventilation Systems

- Supply Air Ventilation Dampers

- Diffusers for Ventilation Systems

- Mobile Air Conditioners | for Indoor Climate Control

- Domestic | industrial air purification systems

- Special products and accessories

- Other products

- Safety tools

- Quality used products

-

Security and Surveillance Systems

- ABOUT US

To get free delivery spend additional

200000€ VAT incl.

We will deliver for free!

Up to the minimum order amount left

500€ VAT incl.

UAB Elektrotechnikos sprendimai

© 2024 Elektrotechnikos sprendimai, UAB. Without Elektrotechnikos sprendimai, UAB confirmation any use or copying of site content is prohibited.